Meet Our Team

Our employees are skilled craftsmen who take pride in their work and are dedicated to our client’s success.

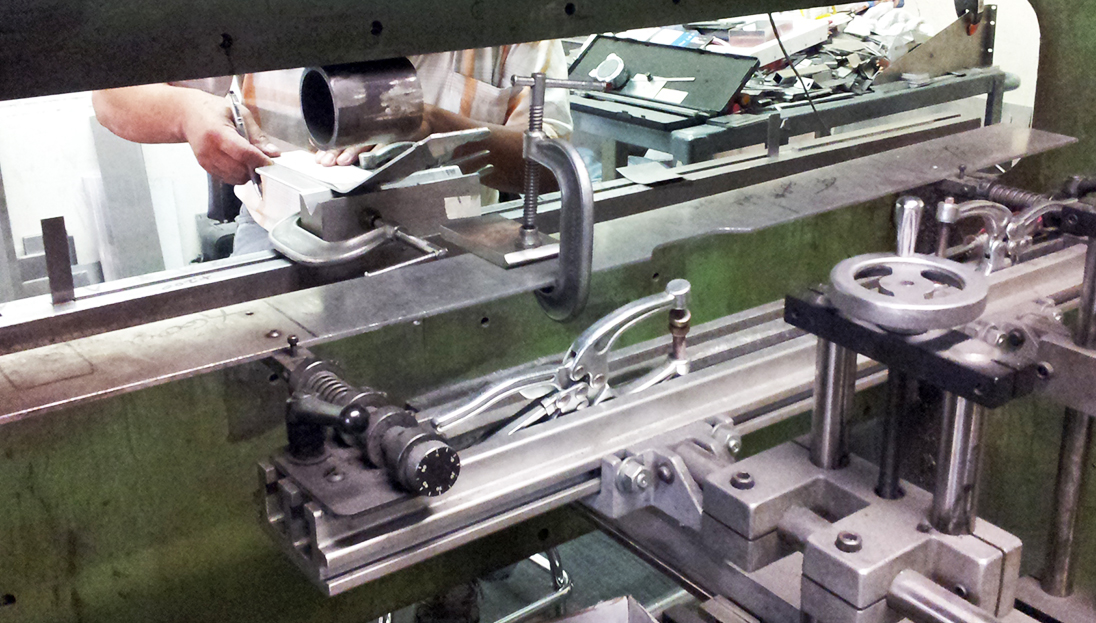

Scott Stahler

Scott Stahler

President and Co Owner

With 30 years in sheet metal fabrication and product development, Scott helps clients to turn innovative ideas into physical products.

Scott entered the sheet metal fabrication world following a successful career in the film industry. He work in production and post production on major television shows and feature films like; The Shawshank Redemption and The Wonder Years. Check out his IMDB for more information.

In 1994 Scott retired from film and TV after his first son was born and decided to join the family business, Hamilton Metalcraft. He made it a point to mix his art and entertainment background with his knowledge of sheet metal fabrication. For Scott, manufacturing is an art.

On his free time, Scott loves listening to music, watching Spaghetti Westerns and going to baseball games, he can regularly be found at Dodger Stadium.

Juan Euyoque

Juan Euyoque

Foreman and Co Owner since 2019

Creative and resourceful, Juan has been instrumental in helping customers develop new and unique designs that are durable and affordable. Juan handles day to day operations and on-site inspections, ensuring jobs are on time and the highest possible quality.

Juan is an Autocad expert, regularly using Solidworks and Inventor. He’s responsible for the shops unique ability to do rapid prototyping and reverse engineering. We’ve seen Juan turn a napkin blueprint into a finished product.

Juan joined Hamilton Metalcraft in 1998 after earning an Applied Science Degree in Computer-Aided Drafting Technology. In his free time Juan can be found hanging out with his family, playing soccer or fixing up his 1988 Z28 Camaro.

Cliff Johnson

Cliff Johnson

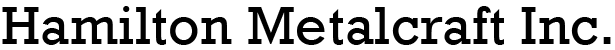

Punch Press Operator

Vastly experienced, dedicated, and passionate about his work, Cliff has been sharing his positive attitude with Hamilton Metalcraft since 1979. Cliff offers an incredible attention to detail, impressive work ethic, precision output, and efficient processes that ensure his clients benefit from fast turnaround of their orders.

When Cliff isn’t operating the punch press or boosting company morale, he can be found surfing and spending time with his wife.

Gersayn Benitez

Gersayn Benitez

Certified Welder

Gersayn is an extremely talented welder, who takes immense pride in his work. He welds with pinpoint accuracy to ensure consistent performance form part to part; and creates perfectly smooth, round edges for a beautiful look and feel. Gersayn’s quality welds never leave bumps or burrs that need to be cleaned later. This means his machine parts pass through the workflow with speed and efficiency to support a faster turnaround for the client.